THRUST our purpose built paramotor wing has claimed worldwide fame as one of the most desirable paramotor wings.

The last THRUST upgrade was in 2009. Feedback accumulated and experience gained, led us to introduce improvements to make this excellent wing even better - as a result THRUST III is born.

In line with our design philosophy, THRUST III now is equipped with SRS® (Stall Recovery System) as standard, in addition to HIT valve and FLEXON batten.

SRS® is designed to be an important safety feature, but above all, it is a great help in improving launch characteristics on gliders when hesistating to come up over head. The THRUST's launch was always spotless, but now its even better - foolproof.

Whatever the pilot will do and despite his best efforts to spoil the launch, the THRUST III will come up evenly, consistently to stay over head, waiting for launch.

THRUST III design is focused on:

- Launch - spotless - no matter wind or no wind, cross or tail on every hill, any time of the year - easy as never before

- Ground Handling THRUST III positions itself over head with no effort and just hovers there even in the slightest wind with no sign of collapse, waiting for the pilot to be ready to accelerate into the air

- In the air the wing acceleration is smooth, and THRUST III willingly responds to the engines thrust

- Handling - light, precise, immediate

- Flying - awesome

- Safety unshakable

- Landing piece of cake!

Out of gas (expensive today)

THRUST III is well suited to free flying too and can be supplied with paragliding risers on request.

THRUST - Roar of the Engine - Whisper of the Wing

The Thrust comes in an ergonomic rucksack incl. an inner stuff bag, compression strap, spares kit, owner's manual and an industry first 3 yr/250 hr warranty - all as standard.

- DESIGN FEATURES

- TECHNICAL DATA

- CERTIFICATION

- PERFORMANCE

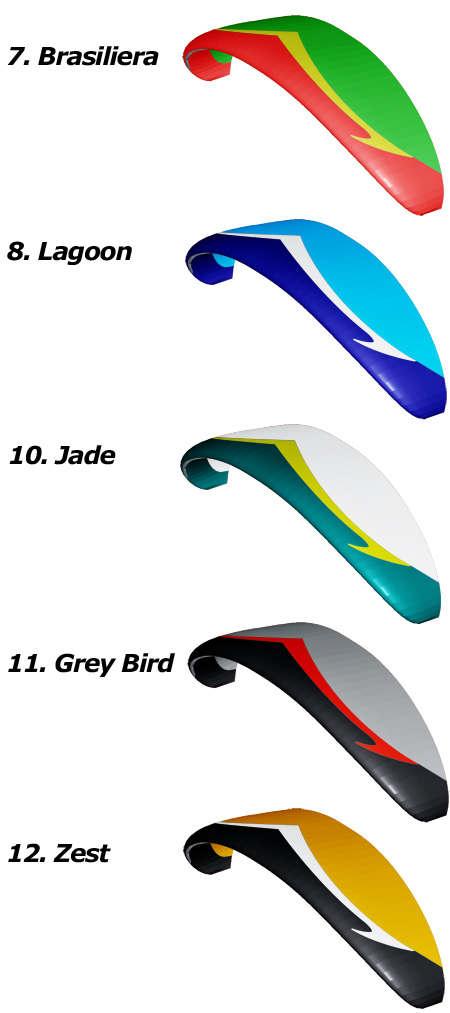

- COLOR OPTIONS

- CONSTRUCTION AND MATERIALS

- HIT valve® equipped on L/E for rock solid stability

- SRS® - APCO exclusive Stall Recovery System for perfect launch and safety

- Flexon® battens system for ultimate durability - pioneered by APCO

- Replaceable trim webbing and camet buckle trim webbing and camet buckle for long-lasting trouble-free service

- Brake handle with swivel and neodynium magnets, inline with our latest technology

- New color design making it more appealing, stands out in the crowd

- Diagonal rib structure - exclusive to APCO

- Split A riser

- All metal parts Stainless Steel or Aluminium

- Eliptical planform

- Butt Holes

- Heavy duty Technora lines

- Double coated siliconised cloth

- Riser with accelerator and trim (for paramotor version), featuring 2 different levels of hook-in points enabling the THRUST to be fitted to any frame and capable of huge safe, speed range thanks to APCOs exclusive HIT® valves (well over 50km/h)

Flexon battens® , HIT Valves ® , and SRS® are exclusive APCO innovations, often imitated, never matched!!

| Small | Medium | Large | X-Large |

| Product Code | 22100 | 22200 | 22300 | 22400 |

| Cells | 42 | 44 | 46 | 48 |

| Area [m2] | 27.3 | 29.3 | 31.3 | 33.3 |

| Area (projected) [m2] | 23.4 | 25.2 | 26.9 | 28.6 |

| Span [m] | 11.58 | 12.20 | 12.90 | 13.50 |

| Span (projected) [m] | 9.32 | 9.85 | 10.4 | 10.9 |

| Aspect Ratio | 4.91 | 5.08 | 5.31 | 5.47 |

| Aspect Ratio (projected) | 3.71 | 3.85 | 4.02 | 4.15 |

| Pilot Weight (all up) P/M [kg] | 70-115 | 85.135 | 100-155 | 110-180 |

| Pilot Weight (all up) P/G [kg] | 65-85 | 80-100 | 95-120 | 110-140 |

| Canopy Weight [kg] | 5.7 | 6.0 | 6.3 | 6.6 |

| Root Chord [m] | 3.03 | 3.03 | 3.03 | 3.03 |

| Tip Chord [m] | 0.58 | 0.58 | 0.58 | 0.58 |

| Length of Lines on B [m] | 6.6 | 7.0 | 7.4 | 7.7 |

| Total Length of Lines [m] | 407 | 421 | 441 | 481 |

| Size | Certification Type |

| Small | CEN/AFNOR Standard Class |

| Medium | CEN/AFNOR Standard Class |

| Large | CEN/AFNOR Standard Class |

| X-Large | CEN/AFNOR Standard Class |

|

| V-min [km/h] | 21 |

| V-trim [km/h] | 37 |

| V-max P/M Version [km/h] | 50 |

| V-max P/G Version [km/h] | 45 |

| Min Sink [m/s] | 1.1 |

Materials

The glider is made from tear resistant Ripstop Nylon cloth, which is P.U. coated to zero porosity and then siliconized to give the fabric high resistance to the elements. Different cloth is used for the top, bottom and ribs due to their different functions. The lines are made of superaramid covered with a polyester sheath for protection against UV, wear and abrasion. The bottom section of the brake lines is made of polyester because of its better mechanical properties. The karabiners that attach the lines to the risers are made of stainless steel.

| Fabric | |

| Sail Cloth | 42 g/m2 "Zero Porosity" Ripstop Nylon |

| L/E Reinforcement | FLEXON® batten system |

| Warranty | 3 years / 250 Hours |

| Material | Diameter [mm] | Strength [kg] |

| Top | Dyneema | 1.1 | 95 |

| Middle A/B/C/D | Super Aramid | 1.2 | 110 |

| Bottom L/XL | Super Aramid | 1.8 | 220 |

| Bottom S/M | Super Aramid | 1.5 | 155 |

| Center Bottom (A/B) L/XL | Super Aramid | 1.9 | 320 |

| Center Bottom (A/B) S/M | Super Aramid | 1.8 | 220 |

| Brake Cascades | Dyneema | 1.1 | 95 |

| Steering Line | Polyester | 2 | 85 |